Sue Madden

Sustainable Art

The River

In 2015 I moved to a house within sight of the River Kent. After only a couple of months the river decided to introduce itself properly, surging down the road during Storm Desmond, although it stayed politely outside the gate. Since then I have continued to have a close relationship with the Kent. I watch its different moods, sometimes welcoming and sometimes hostile, and sometimes it shares its treasures with me; kingfishers, otters, dippers and dabchicks, and once a sparrow hawk having a wash. I have walked both sides of the river from its source in Hall Cove to its mouth where it spills into Morecambe Bay although exactly where it starts and ends are something only the river itself knows.

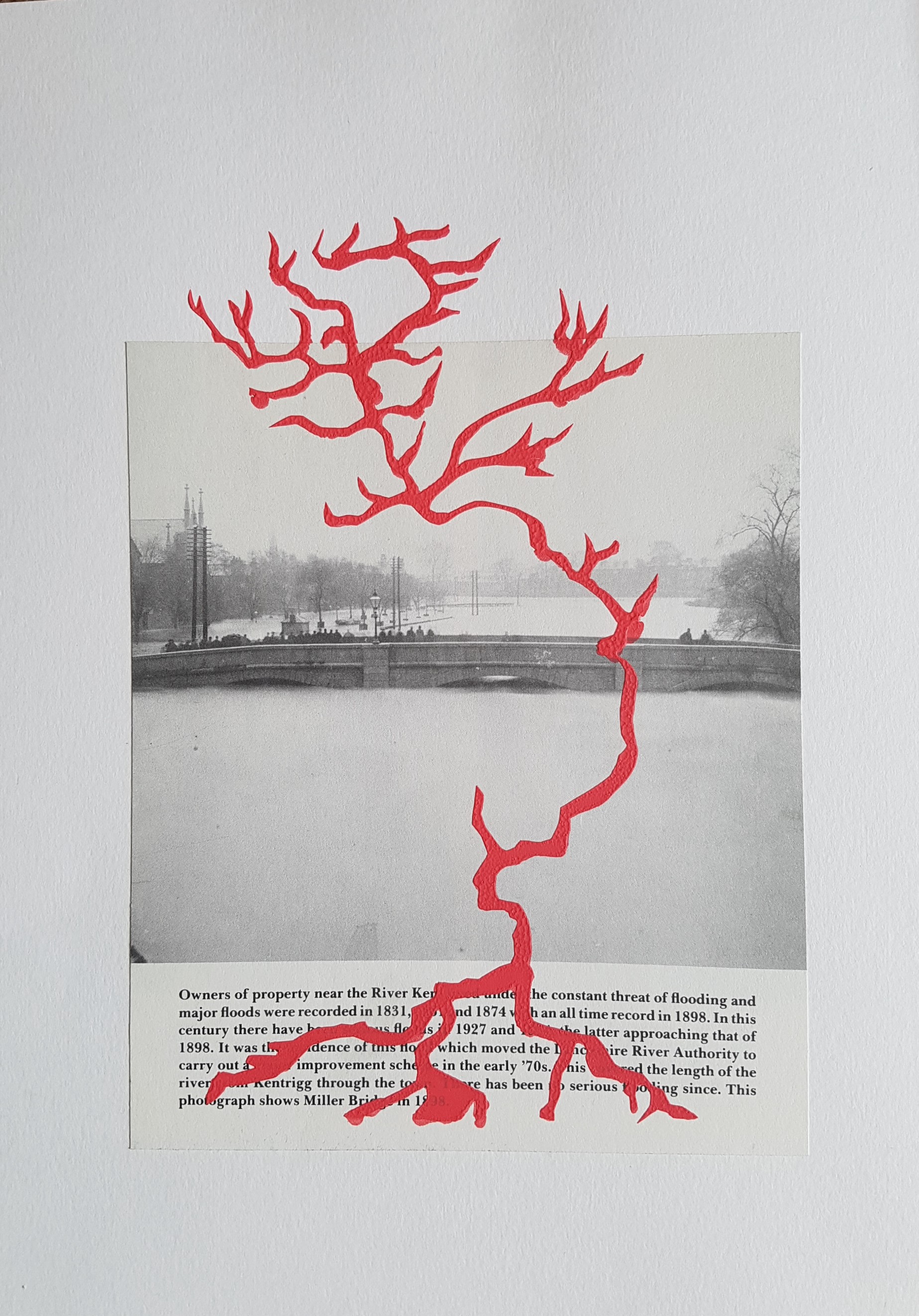

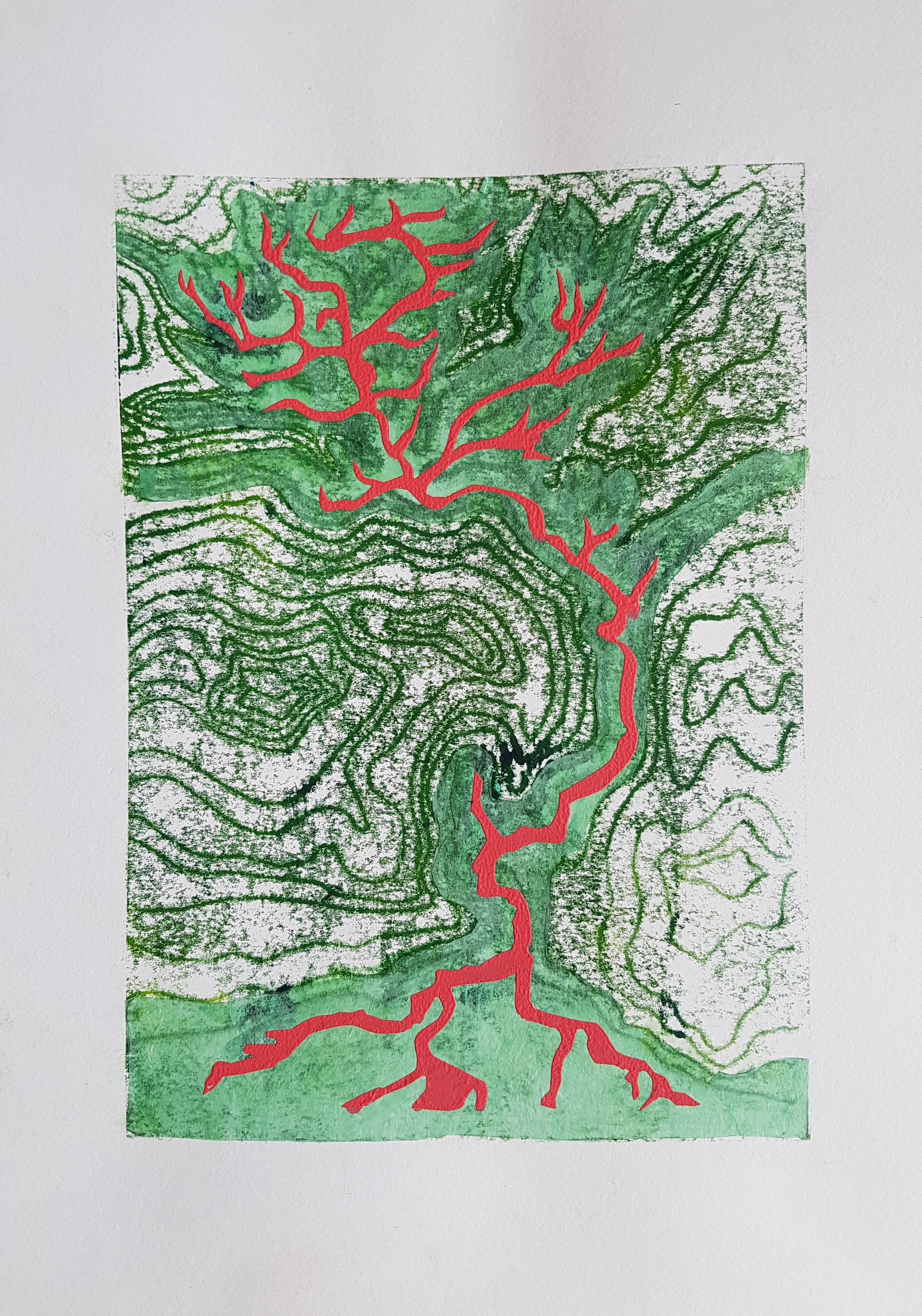

Top row – A set of prints focusing on the River Kent using a combination of printing techniques including intaglio, lino-cut, stencil and photographic silk screen printing.

Bottom row – These two prints were created in response to the Clean River Kent Campaign and reflect hope for the future through both the campaign itself and particularly the involvement of young people. http://www.sustainablestaveley.org.uk/our-projects/clean-river-kent-campaign/

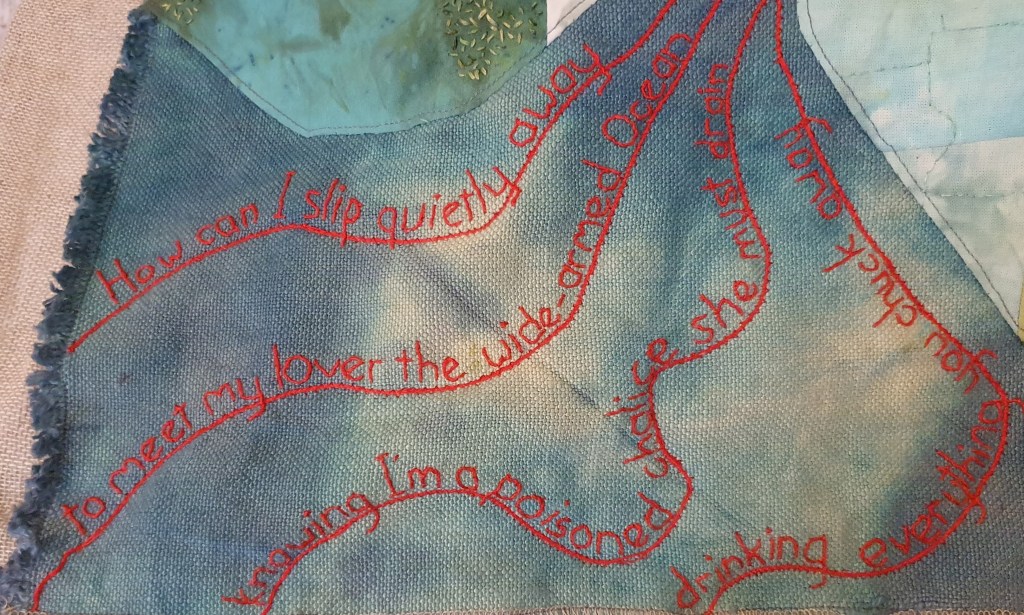

The quilt develops the ideas started in the prints and combines techniques of dyeing, quilting, printing, hand embroidery, and free machine embroidery.

I would like to thank Kathleen Jamie who allowed me to use an extract from her powerful poem ‘What the Clyde said after COP 26’ https://kathleenjamie.com/

Sustainability

Below I have given details of the choices I made in creating this work. These choices are constantly evolving and this information is intended to highlight some of the issues rather than providing answers. Feel free to contact me on the form at the end with any questions or with recommendations if you have come across more sustainable alternatives.

The inks used are all water washable, some are based on linseed oil rather than petrochemicals, but some (screen printing inks) contain plastics. The pigments within inks are synthetic but it takes a great deal of research and is beyond my current understanding to identify whether they are more or less harmful than organic pigments and what issues there may be with industrial pigment production. Releasing even water washable inks into the sewage system places a strain on waste water processing and is a continuing area of research for my practice.

The base paper used is made locally by Croppers. It is machine-made, rather than hand-made, due to cost. The collage elements are from second-hand books and redundant wrapping.

Regarding the print equipment that I employ, the intaglio designs were created using foil covered card, in future I intend to explore using waste materials such as tetra packs. The lino cuts use traditional lino which is biodegradable rather than ‘easy cut’ which is plastic based. The stencils were cut from redundant acetate sheets sourced from Ragtag’s scrap store, https://www.ragtagarts.co.uk/ Photographic silk screen printing employs a reusable screen but requires using a photoreactive coating and a chemical cleaner to remove this. At the present time this seems to be an unavoidable compromise and is therefore kept to a minimum.

The fabric elements were mainly made from redundant material that was hand-dyed using reactive dyes (using the jam jar method and Dylon cold water dye) rather than natural dyes. The choice of dye is a tricky one. While natural dyes seem the obvious choice these take up space in the allotment that could be used for food production; they still need some chemicals as mordants and modifiers: and use large amounts of both heat and water. It is also not clear what impact natural dyes might have when released into the aquatic environment. The reactive dye method uses tiny amounts cold water, salt, and chemical pigment. Whilst I have concerns about the chemical pigments the scales are not always easy to balance, and my choices are always evolving.

The embroidery threads were redundant and have been hand-dyed; the machine threads were purchased new and are 100% cotton. The border is made from new unbleached material that is 50% linen/50% cotton. Ideally, I would use 100% linen as its production uses far less water than cotton and can be produced more locally, but the price of pure linen is unrealistic. The backing fabric is made from a redundant cotton sheet and the internal padding is 50% new cotton bump and 50% redundant polyester filling. It is printed with commercial inks using wood/rubber/lino blocks.